Difference Between Insulated Copper Conductor System And Seamless Conductor Rail

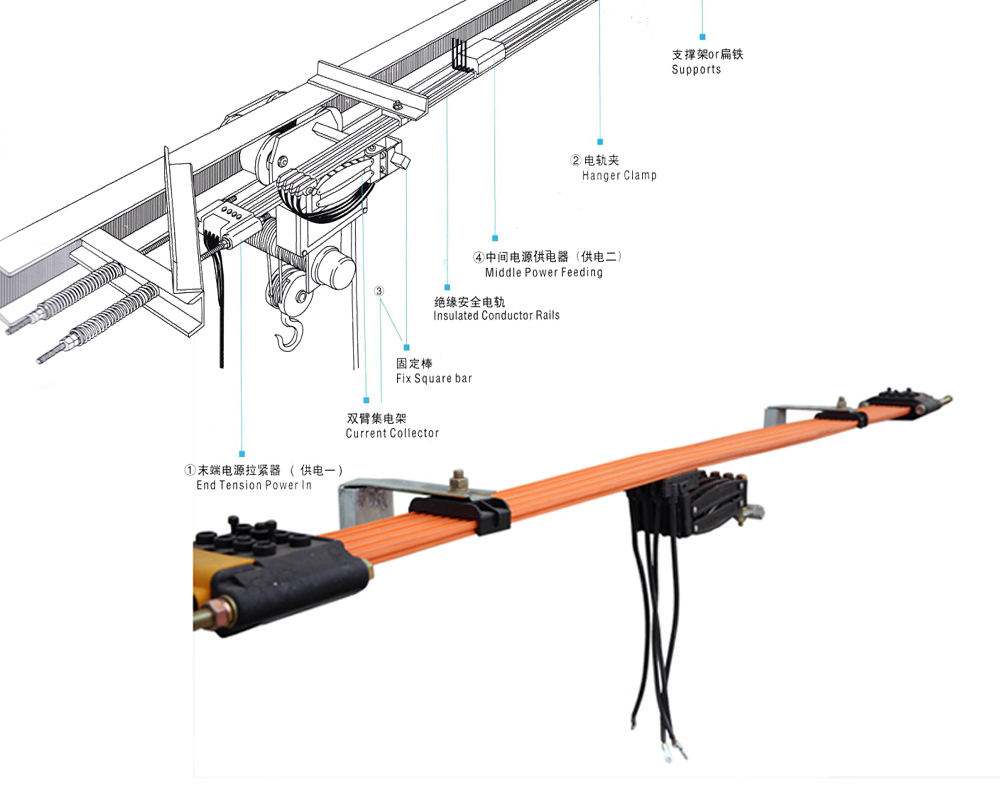

The unique pole insulated conductor bar is composed of copper bars(ground line&phase line), a set of current collector, and other necessary conductor bar spare parts etc., Insulated conductor bar system has advantages of simple structure, low cost, convenient installation and easy maintenance. Installation often adopts three-phase three-wire or three-phase four-wire system, so that this kind of crane conductor bar can withstand more current, each of conductor bar is independent, and if any one conductor bar is damaged, It can be quickly replaced under the conductor rails without damage other sliding conductor. The unique pole insulated conductor rail is made of aluminum alloy conductor or copper bar conductor, which has good electrical conductivity and low electrical resistivity. In additional, the outer housing is made of high-insulation engineering plastic, which provides a guarantee for extending the service life of the sliding wire and improving its safety. Today's standard single-pole conductor bar is usually 4 meters or 6 meters in length, can be customized according to customer demands. Depending on the environment and moving equipment, the unique pole insulated conductor bar is fixed in the middle with a common joint and joint jacket, or an aluminum alloy joint and sheath.Pictures as bellow :

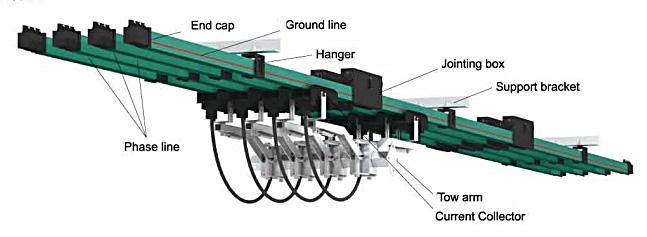

The seamless conductor bar is similar to flat cable, and the sliding wire conductor is sealed with the outer casing, which can be directly laid according to the moving distance of moving device, and the distance required for transmission , not required to be re-connected. So the installation is very simple. The installation form is similar to a single-pole conductor rail , also installed in a three-wire or four-wire system, and the inner conductor is a copper bar. However, the jointless sliding conductor is significantly less flexible than the unique pole insulated conductor bar , and more expensive to use. If any of the copper bars are damaged, the entire crane busbar must be replaced, which leads to higher costs. Moreover, the sliding groove of the jointless sliding conductor is shallow. When the current collector moves in the sliding slot, it is easy to cause power failure, Then the mobile device cannot work normally and cause loss. However, the jointless sliding conductor is widely used, flexible in use, no need for connectors, and can be directly connected to power supply, also favored by some customers. Pictures as follows :